- A multitude of commercial/industrial markets are ripe for penetration for the right graphene producer

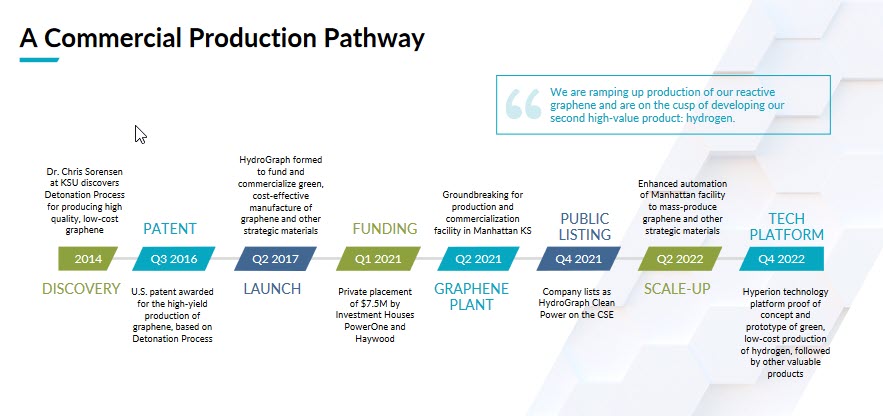

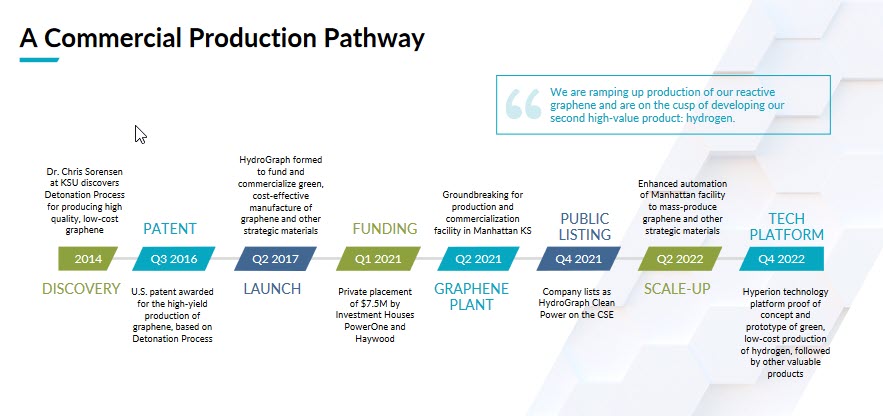

HydroGraph Clean Power Inc (CAN:HG / US:HGCPF) is a dynamic junior technology company, still flying under the radar of investors (and analysts) in both of the major technology sectors that it is on the cusp of transforming.

The Company has developed state-of-the-art technology that drives the efficient (and renewable) production of

clean energy and

next-generation materials for the 21st century economy.

HydroGraph has patented technology for

manufacturing high-purity graphene, efficiently and at commercial scale.

HydroGraph has patented technology for

manufacturing hydrogen (the fuel of the

future), efficiently and at commercial scale.

What tips off investors that HydroGraph has pioneered some truly revolutionary technology? The Company uses

the same technological process (its patented

Hyperion Detonation Technology) to produce both graphene and hydrogen.

When Dynamic Wealth Research sat down for a chat with the Chief Executive Officer of HydroGraph, Stuart Jara, he highlighted the impact of graphene on improving materials and industries. Some of the discussion on graphene and HydroGraph’s technology sounded more like science-fiction than science-fact.

Some of the science fiction-like properties of graphene:

- 200X stronger than steel

- 1,000X more current capacity than copper

- Stretches to 120% of size

Graphene is essentially the world’s first two-dimensional material, capable of being produced in sheets as thin as a single atom.

A single-layer sheet of graphene large enough to cover a football field would weigh less than a gram.

HydroGraph is transforming graphene production

Since the 2010 Nobel prize-winning isolation of graphene, the most-common process to produce this remarkable two-dimensional material has been the same. Obtain a supply of high-grade/large-flake graphite and attempt to massage that chemistry into the artificial and extremely potent molecular configuration of graphene.

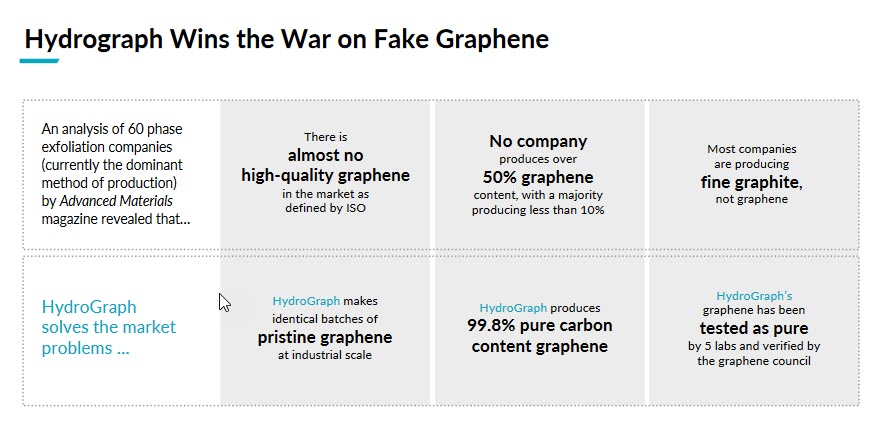

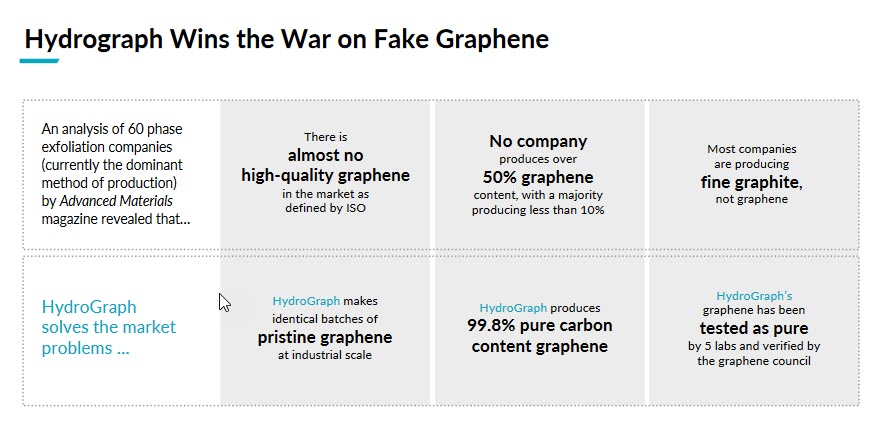

Such processes have produced mixed results, at best. Jara pointed out to Dynamic Wealth Research that according to one industry survey (prior to HydroGraph’s breakthrough) no company produced products with >50% graphene content.

In fact, many “graphene” products on the market today contain less than 10% actual graphene.

[Source: The War on Fake Graphene,

Nature. 2018. With additional HydroGraph content.]

HydroGraph’s unique process for manufacturing graphene

can consistently produce graphene of 99.8% purity. This will allow HydroGraph to supply graphene for even the most-demanding, high-end industrial applications.

Translation: HydroGraph is positioned to maximize margins with its graphene production.

Like spinning straw into gold

In the famous children’s fairy tale,

Rumpelstiltskin was able to spin straw into gold. HydroGraph’s proprietary Hyperion Detonation Technology is equally amazing.

The Company can produce its 99.8%-pure graphene

without any graphite as an input. HydroGraph manufactures its industry-leading graphene using only acetylene and oxygen, two abundant industrial gases.

It gets better.

The conventional process to produce graphene from graphite requires high-grade/large-flake graphite, an extremely scarce commodity.

Ceylon Graphene Technologies, currently the world’s largest Graphene Council Verified commercial producer (

1.8 tonnes of graphene production per year) indicates on its

website that its location (Sri Lanka) is “the only place in the world where vein graphite is found in commercial quantities.”

Ultimately, very limited manufacturing inputs will equate to a very expensive end product.

More significantly, as graphene output expanded (with this conventional process), prices could only steadily rise over the long term – as supply constraints tightened. Once (limited) supplies of large-flake graphite are exhausted, the world would be facing “peak graphene”, even as additional industries are still transitioning toward the use of this

Miracle Material.

This conventional process for producing graphene from graphite is also relatively dirty. HydroGraph’s patented process for manufacturing graphene is the greenest form of graphene production currently on the market (think “ESG”).

CEO Jara contrasted the two manufacturing processes for investors.

“The conventional model for manufacturing graphene is energy intensive, dependent on high quality graphite, and based on large, centralized facilities. HydroGraph’s method has the lowest environmental footprint in the market, produces high purity graphene with near-perfect batch to batch consistency and is designed to be modular for on-site production.”

Using only acetylene and oxygen, both available in plentiful supply, HydroGraph can produce its much ‘greener’ graphene at virtually whatever level of supply is demanded by industry. Scaling-up output

without the need to scale-up price.

Consistent, clean, high-purity, cost-efficient graphene, produced from ordinary industrial gases. Like spinning straw into gold.

The graphene technology of tomorrow, today

The graphene technology of tomorrow, today

Unlike

Rumpelstiltskin, this is no fairy tale.

HydroGraph Clean Power is already in commercial production of graphene at the Company’s Manhattan, Kansas production facility.

HydroGraph is now gearing up for large-scale commercial production of its 99.8%-pure graphene (Q4 2022).

[Source:

HydroGraph Clean Power Inc]

HydroGraph has solved this issue. Unlike most commercial graphene production, the Company’s graphene production “cells” are modular – and extremely compact. No “supply chain”, the graphene production is on-site for its industrial users.

Each HydroGraph graphene production cell is ~2 cubic meters in size, with an annual yield of approximately 12 tonnes of the blackest, highest-quality, most-consistent graphene currently available on the market.

These cells can be used in combination, meaning that HydroGraph can scale-up its modular graphene production to whatever level of demand is required by the end-user.

Stuart Jara envisions HydroGraph adding 15 (or more) of these graphene production cells to supply its clients over the next 12 months. Let’s put that into context for investors.

Just one Hyperion production cell can produce 12 tonnes of industry-leading graphene per year (1 gram per second), which is orders of magnitude greater than the nearest competitor.

An end-user with 15 Hyperion production cells in operation would have

an annual supply of graphene of 180 tonnes.

It doesn’t take a lot of complex math to see that HydroGraph is positioning itself to become the world’s #1 producer of graphene (by quantity), while also producing industry-leading quality.

HydroGraph certified as a leading commercial producer of graphene

As previously noted, a lot of the “graphene” that is currently commercially available is, in fact, more

graphite than graphene. This is fine for lower-end graphene applications such as graphene-enhanced cement and graphene-enhanced steel, for superior construction materials.

However, for high-end applications of graphene in nanotechnology and other cutting-edge 21st century tech, consistent high-purity/high-quality graphene is mandatory.

The quality (and consistency) of HydroGraph’s graphene production has already earned international recognition.

The Graphene Council is the world’s leading authority for the graphene industry. To facilitate graphene commerce and the development of the industry, The Graphene Council has established its Verified Graphene Producer® program,

billed as:

“[T]he only credential that includes independent 3rd party in-person inspections of graphene production facilities, verification of production methods, volumes and quality control processes.”

HydroGraph is currently one of only 4 Verified Producers in the world to have this certification. With its Hyperion Detonation Technology, the Company:

- Produces the highest quality/highest purity graphene;

- Has modular, cost-efficient production that can be rapidly scaled up to virtually any production level required;

- Requires no graphite as a production input;

- Yields clean, green, consistent graphene.

A multitude of graphene markets for HydroGraph

What industrial applications might benefit from the world’s strongest/most-conductive/lightest material?

For starters: cancer detection, night-vision lenses, bullet-resistant armor, solar panels, crop monitoring, quantum computing, drug delivery, water filtration, energy storage, sports equipment, and automobiles.

Graphene’s superior chemical/metallurgical properties also make it a highly desirable input in other industrial products and materials, including

lubricants, coatings, resins, conductive inks, and composite materials.

That is a lot of market opportunities for a Company that (potentially) will soon become the world’s #1 producer of graphene.

However, this isn’t the first rodeo for CEO Stuart Jara. Jara’s 20+ years of executive experience is equally split between public companies (“navigating markets”) and private equity (“getting things done”).

[Source:

HydroGraph Clean Power Inc]

With HydroGraph’s strong positioning as a graphene producer, the Company is being very strategic with its initial target markets.

Jara explains further:

“The applications for graphene are numerous, from textiles to super capacitors and everything in between. We have decided to focus our internal resources on a few key applications at the high end of the market, including lubricants, batteries, composites and coatings, and will partner with other companies on other applications.”

Jara pointed out to Dynamic Wealth Research that, just as with the introduction of aluminum in the 20th century, engineering graphene into the 21st century economy is a difficult but manageable challenge.

For a lot of the graphene applications (listed above), many weeks or even months of work will need to be done to redesign production processes to incorporate this incredible material into the consumer products of tomorrow.

Lubricants, coatings and resins represent markets for high-quality graphene that are already open today, and where graphene can be most-easily incorporated into the manufacturing process.

The other half of HydroGraph’s dynamic hi-tech business model

Given the potential of the Company’s industry-leading commercial graphene production, it would be easy for investors to overlook

the other half of HydroGraph’s business model: large-scale, cost-effective hydrogen production.

Dynamic Wealth Research will be publishing an upcoming full-length feature on the enormous potential of HydroGraph’s hydrogen business model.

As a global “energy crisis” rapidly materializes, hydrogen was already positioned to be the clean fuel of the future. But large-scale adoption of hydrogen as a fuel is still on the horizon.

Graphene commercialization is already here: the hi-tech material of the 21st century economy. All that was missing was a graphene producer capable of producing consistent, high-quality graphene cost-effectively and at full commercial scale.

HydroGraph Clean Power Inc is that graphene producer.

HydroGraph.com

HydroGraph corporate presentation

FULL DISCLOSURE: The writer holds shares in HydroGraph Clean Power Inc. HydroGraph Clean Power is a paid client of Dynamic Wealth Research.

HydroGraph.com

HydroGraph corporate presentation

FULL DISCLOSURE: The writer holds shares in HydroGraph Clean Power Inc. HydroGraph Clean Power is a paid client of Dynamic Wealth Research.